Designing a Collaboration Model among Supply Chain Members and Measuring the Technical Efficiency of Supplier Companies Using Data Envelopment Analysis in the Oil and Gas Industry

Keywords:

Supply chain, technical efficiency measurement , supplier companies, oil and gas industry , data coverage analysisAbstract

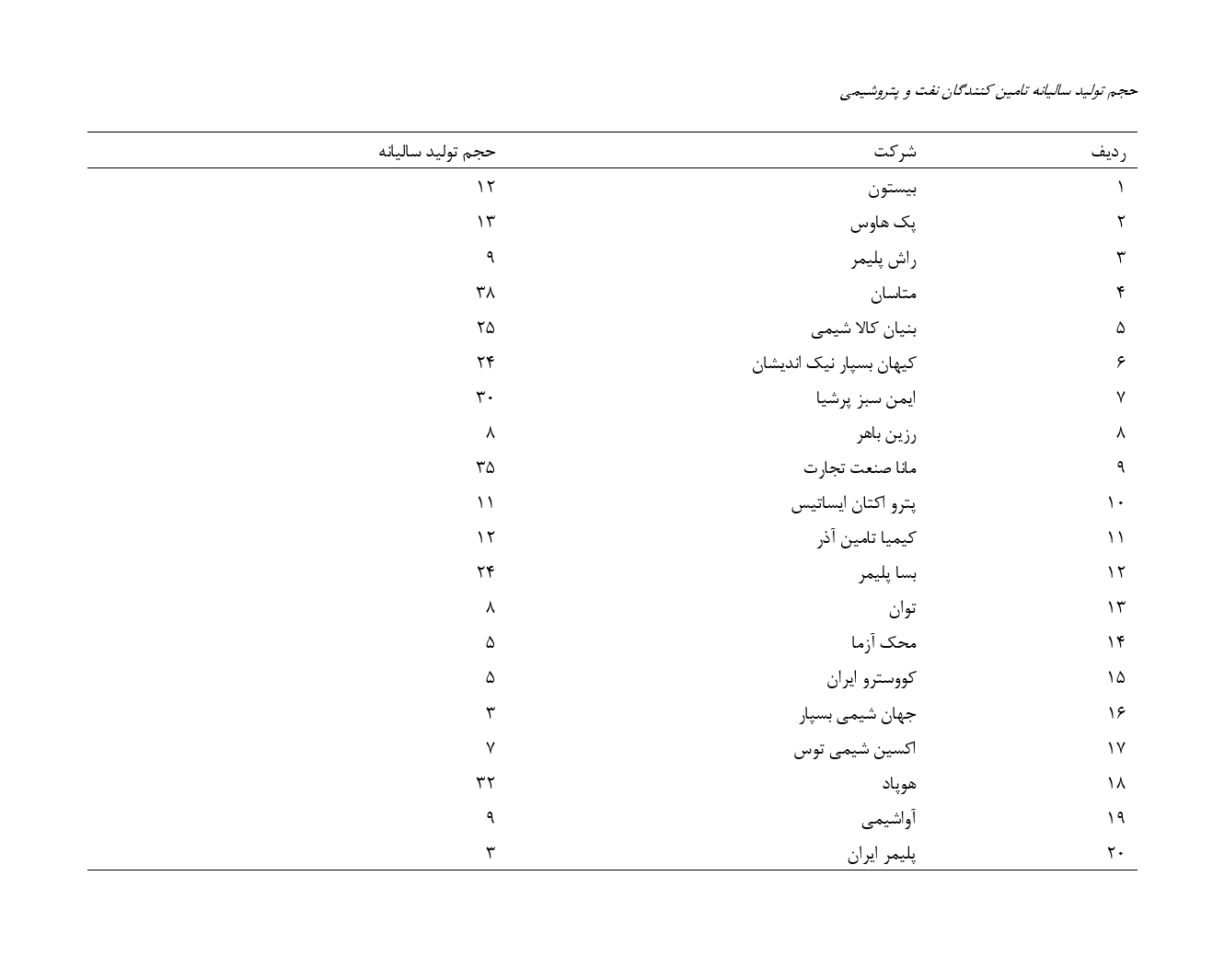

Given the increasing competition among companies and suppliers in the oil and petrochemical industry in the modern era, it has become essential for all active companies in this field to have a thorough understanding of their efficiency levels. They must examine the various causes of efficiency and inefficiency in their units and systematically plan and execute reforms in inefficient units. By enhancing the efficiency of underperforming units, it is expected that national interests will be better and more effectively served, improving the efficiency of the oil and petrochemical distribution and development systems in the country. This study focuses on designing a collaboration model among supply chain members and measuring the technical efficiency of supplier companies using Data Envelopment Analysis (DEA). By examining influential data and outputs, DEA is employed to calculate the technical efficiency of the country’s supplier companies under two assumptions: constant returns to scale (CRS) and variable returns to scale (VRS). The statistical sample consists of 15 experts with academic and practical experience in financial management and stock market operations. The research findings indicate that technical efficiency and pure technical efficiency (PTE) are directly derived from the computation of CCR and BCC models. Under the CRS assumption, the average efficiency of the companies under study is 88.45%. From a geometrical perspective, under this assumption, the production frontier is represented as a straight line on which efficient units are located, forming the frontier. Under the VRS assumption, the average efficiency is 90.88%. This indicates that companies have produced 9.12% less than the optimal amount given their current input levels. Furthermore, under this assumption, the production frontier is concave, and each efficient production unit is positioned on the frontier. The average scale efficiency is 97.17%, implying that the actual production scale deviates by 2.83% from the most productive scale. When pure technical efficiency (PTE) exceeds scale efficiency, inefficiency is due to scale inefficiency. Conversely, when this is not the case, the major portion of inefficiency is attributed to pure technical inefficiency or management (operational) inefficiency.

Downloads

References

Abbas, K., Afaq, M., Ahmed Khan, T., & Song, W. C. (2020). A Blockchain and Machine Learning-Based Drug Supply Chain Management and Recommendation System for Smart Pharmaceutical Industry. Electronics, 9(5), 1-31. https://doi.org/10.3390/electronics9050852

Alizadeh, H., & Ghasemi, M. (2023). The Effect of Tourists' Preferences on the Competitiveness of the Hotel Industry. Quarterly Journal of Tourism Research and Sustainable Development, 5(3), 25-40. https://www.magiran.com/paper/2508703/

Alizadeh, H., & Jalali Filshour, M. (2023). Proposing a Mixed Model of Digital Marketing in the Financial Services Sector with an Emphasis on Artificial Intelligence Tools. 30th National and 11th International Conference on Insurance and Development,

Alizadeh, H., Kheiri, B., & Heiydari, A. (2020). An Investigation of the Brand-Consumer Relationship Model Based on Digital Marketing in the Hotel Industry. International Journal of Management, 11(8), 1075-1093. https://www.researchgate.net/publication/355049567_AN_INVESTIGATION_OF_THE_BRAND-_CONSUMER_RELATIONSHIP_MODEL_BASED_ON_DIGITAL_MARKETING_IN_THE_HOTEL_INDUSTRY

Chopra, S., & Sodhi, M. S. (2021). Managing risk to avoid supply chain breakdown. MIT Sloan management review, 46(1), 53-61. https://sloanreview.mit.edu/article/managing-risk-to-avoid-supplychain-breakdown/

Chu, C. Y., Park, K., & Kremer, G. E. (2020). A global supply chain risk management framework: An application of text-mining to identify region-specific supply chain risks. Advanced Engineering Informatics, 45. https://doi.org/10.1016/j.aei.2020.101053

Huang, J., Huang, H., Si, Y., Xu, Y., Liu, S., & Yang, X. (2024). Green supply chain finance strategies with market competition and financial constraints. Heliyon, 10(8). https://doi.org/10.1016/j.heliyon.2024.e29511

Kannan, G., Haq, A. N., Sasikumar, P., & Arunachalam, S. (2008). Analysis and selection of green suppliers using interpretative structural modelling and analytic hierarchy process. International Journal of Management and Decision Making, 9(2), 163-182. https://doi.org/10.1504/IJMDM.2008.017198

Ningrum, E., Nugroho, A., Darmansyah, D., & Ahmar, N. (2024). A Scoping Review of Green Supply Chain and Company Performance. International Journal of Quantitative Research and Modeling, 5, 26-30. https://doi.org/10.46336/ijqrm.v5i1.608

Olawale, O., Ajayi, F. A., Udeh, C. A., & Odejide, O. A. (2024). Risk management and HR practices in supply chains: Preparing for the Future. Magna Scientia Advanced Research and Reviews, 10(2), 238-255. https://doi.org/10.30574/msarr.2024.10.2.0065

Rajab Pour, F., & Alizadeh, H. (2024). Investigating the impact of environmental factors on the adoption of social media among small and medium enterprises during the Covid-19 crisis. 6th National Conference and 3rd International Conference on New Patterns of Business Management in Unstable Conditions,

Samiei, H. A., Mehrabian, A., Ashrafi, M., & Khamaki, A. (2023). Financial benefits and costs, sustainable supply chain, conditions of uncertainty, manufacturing companies. Journal of value creating in Business Management, 3(3), 41-64. https://www.jvcbm.ir/article_178979.html?lang=en

Shafiee, M., Zare Mehrjerdi, Y., & Keshavarz, M. (2021). Integrating lean, resilient, and sustainable practices in supply chain network: mathematical modelling and the AUGMECON2 approach. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2021.1921878

Shafiei, M., Saleh, H., & Qaderi, M. (2021). Modeling in the Supply Chain Using Data Envelopment Analysis and System Dynamics Simulation.

Udofia, E. E., Adejare, B. O., Olaore, G. O., & Udofia, E. E. (2021). Supply disruption in the wake of COVID-19 crisis and organisational performance: mediated by organisational productivity and customer satisfaction. Journal of Humanities and Applied Social Sciences, 3(5), 319-338. https://doi.org/10.1108/JHASS-08-2020-0138

Zhang, X., & Yousaf, H. (2020). Green supply chain coordination considering government intervention, green investment, and customer green preferences in the petroleum industry. Journal of Cleaner Production, 246. https://doi.org/10.1016/j.jclepro.2019.118984

Downloads

Published

Submitted

Revised

Accepted

Issue

Section

License

Copyright (c) 2024 Journal of Technology in Entrepreneurship and Strategic Management (JTESM)

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.